Electrical Panel Repair Houston: Breaker Replacement Experts

Houston homes work hard. Air conditioners cycle through brutal summers, pool pumps hum, EV chargers sip power overnight, and kitchen remodels add new loads that old systems were never meant to carry. When the electrical panel starts to fall behind, it doesn’t complain politely. It trips at the worst time, throws a burning odor, or leaves half the house dead while the fridge keeps running. That’s when a seasoned technician earns their keep. Electrical panel repair is not glamorous. It is methodical, code-driven, and safety-critical. Done well, it extends the life of the system and restores confidence. Done poorly, it creates hazards you can’t see until they bite.

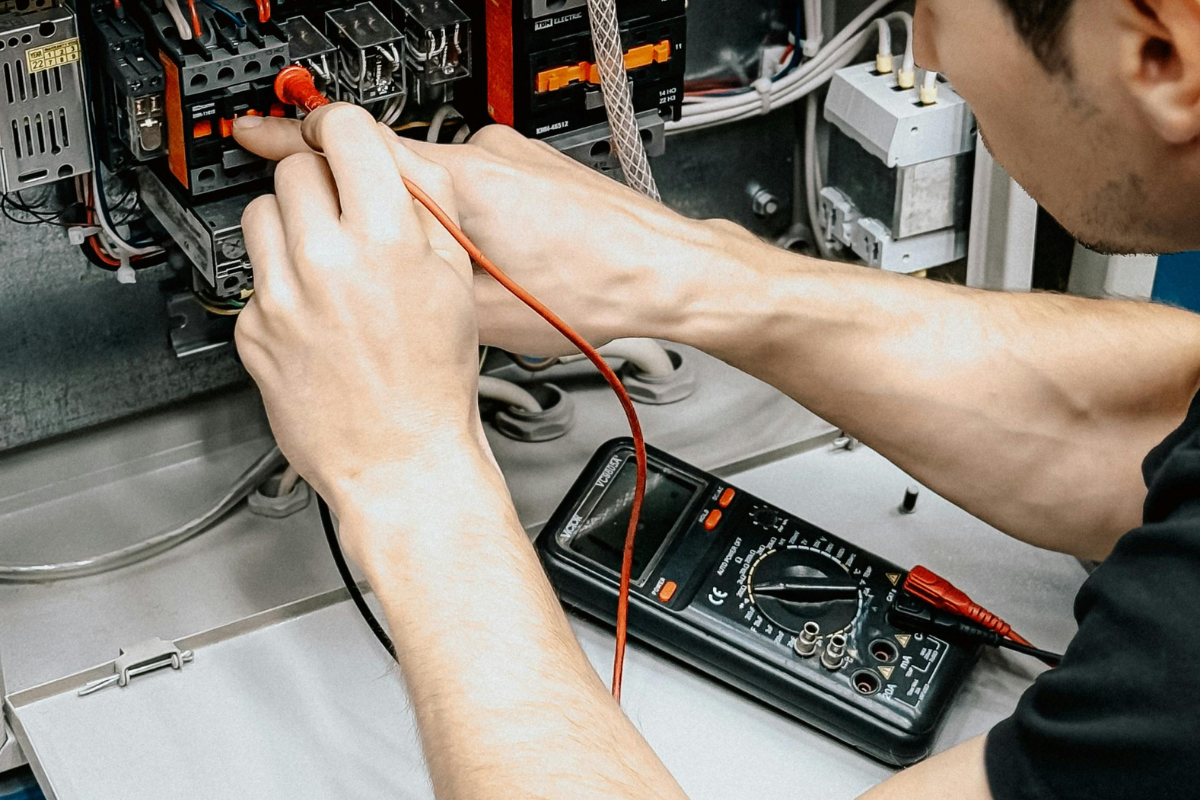

I have spent long days in tight garages and sweltering attic spaces across Harris and Fort Bend counties, handling breaker replacements, panel rebuilds, and complete service upgrades. The patterns are familiar, but every job carries its own fingerprint. The best electrical repair services bring experience and judgment to that specific mix of equipment, load, and code in front of them. What follows is a practical guide to how pros approach electrical panel repair and breaker replacement in Houston, when to repair versus replace, what it should cost, and how to recognize work you can trust.

What a Panel Actually Does, and Why Houston Punishes It

An electrical panel is a distribution hub. Power arrives surge protection from the utility through the meter and main disconnect, then divides into branch circuits through breakers sized for wire gauge and load. It sounds straightforward until you factor in decades of changes. A panel installed in 1988 might have been sized for a 2,000 square foot home with a single oven and modest HVAC. Thirty-five years later, that same home might have a double-oven range, a 5-ton high-efficiency condenser, more lighting, and a 50-amp EV charger. The original main lugs, bus bars, and neutral/ground bars must still carry the current without overheating or arcing.

Houston adds a few twists. Humidity fogs metal surfaces and accelerates corrosion. Rodents chew through attic cable runs, and flood events leave hidden residues inside service equipment. Fast-cycling air conditioners along with high ambient heat multiply thermal stress on breakers. Add in lightning-heavy storm seasons that surge and spike the line. If panels had odometers, Houston’s would read high.

Signs Your Panel Needs Attention Beyond a Reset

The first rule in residential electrical repair is to respect repeated symptoms. One random trip might be a nuisance. A pattern of trips, heat, or intermittent power tells a story you should not ignore.

Look for these signs as objective clues:

- Recurrent tripping on the same breaker, especially under modest load or at startup for a known appliance.

- Warm or buzzing breakers, or a panel cover that feels warmer in one area than the rest.

- Flickering or dimming lights when large loads kick on, especially if the flicker spreads across rooms on different circuits.

- Burn marks on breaker handles, scorch marks near the bus, or a faint metallic or smoky odor at the panel.

- Rust, white powdery corrosion, or moisture evidence inside the dead front.

Those are not cosmetic issues. Heat at a breaker face often means a poor connection at the bus stab or a deteriorating breaker spring. Corrosion at neutral bars can elevate resistance, introducing voltage imbalances that show up as dimming lights and odd appliance behavior. A good technician will isolate the fault quickly with a mix of inspection, thermal scanning, and metering.

When a Breaker Is the Culprit, and When the Problem Runs Deeper

Homeowners often assume any trip means the breaker is bad. Sometimes that is true. More often, the breaker is doing its job. The root cause could be a short in a receptacle, loose set screw on a neutral, an overloaded multi-outlet circuit feeding a kitchen full of countertop appliances, or a deteriorated motor in a condensing unit. I’ve replaced my share of breakers only to find the new part trips the moment a ground fault downstream reappears.

Here is how pros separate panel issues from branch circuit problems. First, we verify load and fault conditions. For thermal trips, we look at what runs when the breaker trips. For instantaneous trips, we suspect a short. For classic “runs fine for hours, then trips,” we consider heat buildup at a lug or bus connection. We check torque on breaker terminals and neutral/ground bars. On circuits with GFCI or AFCI protection, we test with a known-good load, then isolate downstream devices one by one. If the breaker stabs are discolored or the metal fingers show pitting, we pull the breaker and inspect the bus. Damage there must be addressed or the new breaker will fail too.

If you have an older panel with brand-specific weaknesses, such as certain Zinsco or Federal Pacific Electric models, we do not waste time trying to coax them along. In those cases, even a small electrical wiring repair can turn into a broader conversation about replacement. Not every vintage panel is a problem, but several well-documented lines have earned their reputations.

Breaker Replacement, Done Right

Replacing a breaker is not a glamorous task, but it is easy to get wrong. The part must match the panel series, the amp rating must match the wire gauge and load, and the function must match the circuit. You do not substitute a standard breaker for a required AFCI or GFCI device. You also do not “upsize” a breaker to stop nuisance trips. Upsizing on undersized wiring invites fire.

A proper replacement starts with identifying the panel model and verifying breaker compatibility. Cross-brand breakers that “fit” physically are a frequent cause of heat and arcing, because the contact design varies between manufacturers. A professional will use a listed breaker for the specific panel series. Next, we examine the conductor insulation for heat damage and trim back to clean copper if needed. We clean the bus, check for pitting, and torque to manufacturer specifications, usually with a calibrated screwdriver. Before closing the panel, we meter voltage on both legs, check for balanced load, and verify that the new breaker holds under a known load. It is a simple recipe that prevents call-backs.

Arc Faults, Ground Faults, and the Code Reality

Houston follows the National Electrical Code, enforced by local AHJs, with homeowners in unincorporated areas also subject to utility standards. Over the last cycles, code has expanded the use of AFCI and GFCI protection. That means newer circuits must have breakers that detect arc faults or ground faults, not just overcurrent. Many homeowners upgrade a kitchen or bedroom and end up with a mix of legacy circuits and modern protection. The result can be frustration: a generator transfer switch that trips an AFCI, a treadmill that arcs under startup, or a refrigerator on a GFCI that trips during a defrost cycle.

A seasoned residential electrical repair technician will map the circuits, identify where AFCI or GFCI is required, and, where permitted, move nuisance-prone loads to a dedicated circuit with the right form of protection. We do not “downgrade” protection to stop trips. We solve the wiring and load side. In older homes, that often means separating shared neutrals, repairing splices in the attic, or moving a garage fridge to a circuit that meets both code and practicality.

Panel Repair Versus Full Replacement

Not every tired panel needs to go straight to the dumpster. I have rebuilt panels that were structurally sound, with good bus bars and a solid enclosure, by replacing a handful of breakers, tightening terminations, re-landing neutrals properly, and adding a whole-home surge protective device. That saves cost and downtime. The key is to evaluate the panel’s backbone, the bus and the enclosure.

Consider replacement when:

- The bus shows significant pitting or heat damage, or breakers fit loosely and rock on the stabs.

- The panel is an obsolete or recalled line known for failures.

- The load calculations show your main service is undersized for present and planned loads.

- Corrosion is widespread, particularly after flood exposure.

- You are adding large loads like a 50-amp EV circuit, and the existing panel is maxed out with tandem breakers and no spare capacity.

If the service drop, meter base, and grounding electrode system also need work, a full service upgrade may be the sane path. Houston inspectors look closely at grounding, bonding of metal piping, and the separation of neutrals and grounds in subpanels. It is a good time to correct past shortcuts.

The Hidden Work That Keeps Panels Safe

Most homeowners never see the small tasks that support panel health. Torque matters. Manufacturers publish torque specs for lugs and breaker terminals because loose connections heat up under load. Overtightened lugs can damage conductor strands, which also leads to heat. A good technician uses a torque screwdriver and verifies each termination. We also confirm neutrals are single-lugged. Two neutrals under one screw is still a common sight in older work, and it is not acceptable. Grounds can share, neutrals should not.

Labeling is more than courtesy. Clear circuit directories allow quick isolation in an emergency and help future electricians avoid needless trial and error. During panel work, we test and correct labels. We pull on each conductor to confirm it is secure. We keep neutrals and grounds separated in subpanels and bonded in the service equipment only. These basics turn a simple electrical panel repair into a reliable result.

Surge Protection Is Not a Luxury Here

Thunderstorms in the Gulf region produce frequent surges. Sensitive electronics, including variable-speed HVAC boards, induction ranges, and routers, do not shrug off transients the way an incandescent bulb once did. A whole-home surge protective device installed at the panel, backed by point-of-use protectors for critical gear, reduces nuisance failures. It is not a substitute for proper grounding and bonding. It works with a solid grounding system to shunt surges safely. Many electrical repair services now include surge protection by default when performing panel work because the incremental labor is minimal and the benefit is tangible.

Load Calculations and Modern Living

One of the most useful tools in residential electrical repair is a proper load calculation. Software makes it faster, but the principles are old: account for general lighting loads by square footage, add fixed appliances, apply demand factors, and include heating or cooling depending on the dominant load. EV chargers and spas push many homes over the residential electrical panel repair threshold where a 100-amp or 125-amp service feels cramped. If your panel is full of tandem breakers, that is a sign you are at the physical capacity limit, which is not the same as service ampacity. A IEC/NFPA code compliant electrician load calculation clarifies whether you need a new subpanel for space or a service upgrade for capacity.

In Houston, I often see 150-amp services in 1970s homes that now support a pool pump, outdoor kitchen, and a workshop. You can sometimes make that work with careful circuit management and time-of-use planning, but the margin is thin. If you suffer frequent nuisance trips during peak summer afternoons, it might be the system telling you it has no cushion left.

Safety Practices You Should Expect From a Pro

When you bring someone in for electrical repair Houston style, where heat and fast weather changes challenge equipment, you deserve a clear process. Here is the standard I hold crews to. It is short because it must be memorable.

- De-energize and verify, not just at the breaker but with a meter. Lockout where feasible.

- Cover live parts if the main cannot be shut off, and use insulated tools and PPE for any work near energized service conductors.

- Use listed, manufacturer-approved parts and follow torque specs.

- Take photos of the interior before and after. Good for you, good for the permit, good for the next tech.

- Clean up, label circuits clearly, and walk the homeowner through what changed.

That short list hides a lot of detail, but it captures the discipline behind reliable residential electrical repair.

Common Houston Scenarios From the Field

A two-story in Cypress with flickering lights during AC startup. The panel looked fine at a glance. Infrared showed a hotspot at a double-lugged neutral, shared by upstairs lights and a bedroom circuit. The loose neutral created voltage fluctuation under compressor inrush. We separated the neutrals, retorqued the bar, and the flicker vanished. Not a breaker problem at all, yet the homeowner had replaced three breakers before calling.

A bungalow in the Heights with a Zinsco panel and a new EV charger. The charger tripped intermittently, and the panel emitted a faint buzz. Pulling a breaker revealed a discolored bus with clear signs of arcing. We proposed a full service upgrade to 200 amps with a modern panel and space for future loads. The homeowner wanted a band-aid. We explained the risk plainly, showed the physical evidence, and let them decide. They chose the upgrade and later told me the peace of mind alone was worth it.

A newer build in Katy with nuisance AFCI trips in a home office. The culprit turned out to be a budget power strip and a laser printer on the same circuit. AFCIs do not love certain switching power supplies. We added a dedicated circuit for the office equipment with the required protection and swapped the suspect strip for a better one. The homeowner learned why the cheapest power strips cost more in the long run.

Permits, Inspections, and Working With the Utility

Not every breaker swap needs a permit, but panel repairs and service upgrades usually do. In Houston, pulling a permit and scheduling an inspection protects you and ensures the work meets current standards. Inspectors look for proper working clearance, correct bonding, service conductor sizing, drip loops and service mast integrity where applicable, and proper labeling. If the work touches the meter base or service drop, the utility gets involved. Timelines vary, but with coordination you can minimize downtime. Temporary power solutions exist for longer outages, yet most panel repairs and swaps can be completed in a day once materials and permits are ready.

What It Should Cost, and What Drives Price

Costs vary with scope, access, and parts. As a ballpark based on recent jobs:

- Single breaker replacement using a standard breaker: often 150 to 300 including diagnosis and testing. AFCI or GFCI breakers cost more, sometimes pushing the total to 250 to 450.

- Partial panel rehab: cleaning and retorquing, replacing several breakers, correcting neutrals, adding a surge protective device: typically 600 to 1,200 depending on parts and condition.

- Full panel replacement without service upgrade: often 1,800 to 3,500 including permit and inspection, influenced by brand, number of circuits, and any relocation or drywall work.

- Service upgrade from 100/125 amps to 200 amps: commonly 3,500 to 7,000, higher if trenching, meter relocation, or mast reconstruction is required.

Flood remediation, corrosion repair, or rewiring downstream circuits can add to the total. Honest electrical repair services explain each cost driver and provide options. If a quote feels vague, ask for clarity. A good contractor will walk the panel with you and point to the evidence behind each recommendation.

Insurance, Warranties, and Keeping Records

Panel work sits at the intersection of safety and property value. Insurance carriers increasingly ask about electrical system age and condition. Documented repairs and upgrades, with permits and final inspections, can help with premiums and claims. Keep the invoice, permit number, and photo documentation. Many contractors warranty workmanship for one to two years and pass through manufacturer warranties on breakers and panels. Surge protectors often have connected equipment guarantees that require proper documentation.

DIY Boundaries and When to Call for Help

Plenty of home maintenance suits a skilled DIYer. Electrical panel repair is rarely one of them. You cannot learn safe work around service conductors from a video. The risk profile is different, and the mistakes are expensive. If you want to support the process, map your circuits, create a list of symptoms with dates and loads running at the time, and clear access to the panel with the required working space. That preparation saves time and money without putting you in harm’s way.

For minor electrical wiring repair tasks away from the panel, like replacing a faulty receptacle or switch, a competent homeowner can succeed if they turn off the correct breaker, verify de-energized conductors with a meter, and wire devices to code. If anything about the wiring colors, box fill, or grounding confuses you, stop and call a professional. The line between a tidy fix and a hidden hazard is thin.

Choosing the Right Partner for Electrical Repair Houston Needs

In a market crowded with options, look for substance over flash. A credible residential electrical repair contractor will ask more questions than they answer during the first call. They will talk about symptoms, not just prices. They will carry replacement breakers from the correct manufacturer, not a bin of “universal fits.” They will tell you when a repair is enough and when replacement is prudent. They will not upsize breakers to mask a load problem. They will discuss panel rewiring permits without waiting for you to bring it up.

References and reviews matter, but the walk-through tells the real story. If the technician removes the dead front, inspects the bus, torques terminations, and tests under load before recommending work, you likely have a pro. If they stay at the doorway and sell you a new panel in five minutes, keep shopping.

A Final Word on Reliability

Power should feel invisible. When a panel needs care, it makes itself known in trips, flickers, and heat. Those are chances to intervene before damage spreads. Thoughtful home electrical repair restores that invisibility, not by patching symptoms but by addressing the causes: load imbalances, weak terminations, incompatible parts, and protection gaps. In Houston’s climate and with Houston’s loads, reliable panels do not happen by accident. They come from disciplined work, matched parts, and respect for the code that is written in the lessons of past fires.

If your panel has started to talk through trips and flickers, listen. Whether it is a simple breaker replacement or a larger electrical panel repair, the right expertise will quiet the noise and give your home the steady backbone it deserves.

All American Electric LLC

Address: 9230 Keough Rd #100, Houston, TX 77040

Phone: (713) 999-3531