Finding Affordable Garbage Disposal Repair Houston: A Buyer’s Guide

Garbage disposals fail in the most inconvenient moments. A jammed impeller or a burnt-out motor doesn’t wait for a free weekend. If you live in Houston, you have plenty of options, but navigating price, quality, and response time can feel like sorting a junk drawer. This guide steps through what typically goes wrong, when to repair versus replace, how to spot a fair quote, and how to find truly affordable garbage disposal repair without gambling on workmanship. I’ll reference common Houston price ranges, what techs look for on service calls, and the trade-offs that matter.

How a Disposal Works, and Why That Matters for Your Wallet

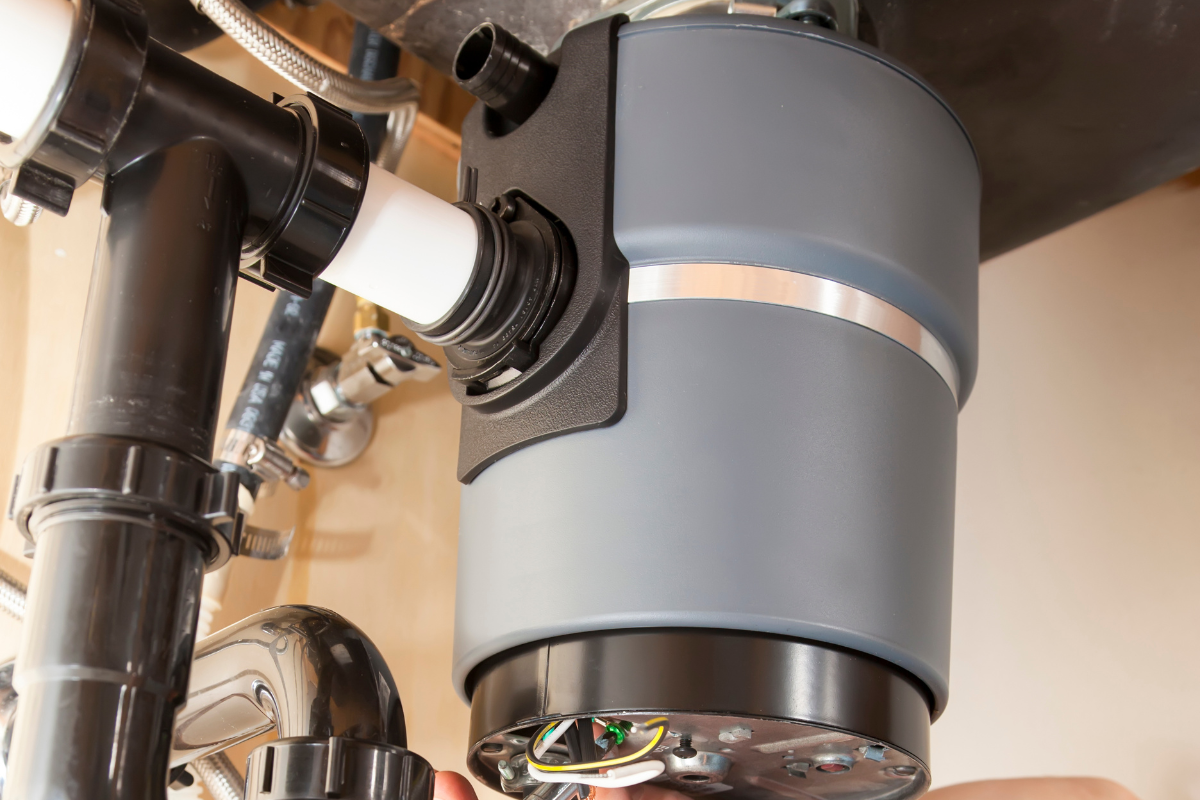

A garbage disposal is a compact electric motor with a grinding chamber and a couple of swiveling lugs, often called impellers. Food scraps enter, the motor spins, water flushes ground particles down the drain. Most residential units fall into 1/3 to 3/4 horsepower. The motor is sealed, and the chamber has a rubber splash guard at the sink throat. A reset button sits on the bottom. Electrical connection can be a plug or hardwired whip. Simple machine, but it sits at the intersection of plumbing and electrical, which is why a technician with both licenses commands a higher rate.

Understanding the guts helps you decide whether a repair is even sensible. Electrical faults, worn bearings, and cracked chambers trend toward replacement. Jams, clogs downstream, or a stuck flywheel are often repairable in one visit. In Houston, a service call that ends with a successful unjam is usually the least expensive outcome.

Common Failures and What They Cost in Houston

Pricing varies by neighborhood and season. After-hours calls run licensed plumber near me more, and high-water events can spike demand. Still, you can think in ranges.

Minor jam or reset. Often caused by fibrous food like celery, onion skins, or a spoon slipping in. A tech may use a 1/4 inch hex key in the flywheel socket and clear it in minutes, then hit the reset. Expect 95 to 180 dollars for diagnosis and fix during regular hours. Some companies waive the diagnostic fee if you approve the repair.

Leak at the sink flange. The putty around the mounting assembly dries out or was too thin from the start. Resealing and remounting takes 45 to 90 minutes depending on rust and access. Typical totals land around 150 to 275 dollars, including new putty and sometimes a new gasket.

Leak from the dishwasher inlet or discharge elbow. Hose clamps loosen or the elbow gasket cracks. Parts are cheap. Labor dominates. Usually 120 to 220 dollars, unless rusted hardware turns it into a wrestling match.

Unit hums but won’t spin. If an Allen wrench clears it and the reset holds, you’re in the minor repair category. If it hums, trips, and repeats, the capacitor or windings may be failing. Capacitor replacement, when feasible and safe, might run 150 to 250 dollars including parts. Burnt windings or a locked rotor usually means replacement.

Persistent clogs. If the trap or branch line downstream backs up, a tech may need to clear the P-trap or snake the line. Expect 150 to 350 dollars depending on how far they have to go and whether a cleanout is accessible. Old galvanized drain lines raise the price and risk.

Cracked housing or internal leak. Disposal housings can corrode from inside out. Once the metal shell or internal seals fail, repair seldom makes financial sense. A replacement is the safer bet.

These ranges assume regular weekday service. Nights or weekends can add 50 to 100 dollars. High-rise condos, tight cabinetry, or nonstandard wiring can slow the job and increase labor.

Repair or Replace: A Practical Decision

There are three questions I ask myself on a call.

How old is the unit? A basic disposal lasts 7 to 10 years in typical use. If yours is pushing that, sinking money into a new motor or a major tear-down is rarely smart.

What is the failure mode? Jams, clogs, and loose flanges favor repair. Housing cracks, burnt windings, and persistent leaks at the motor seal point toward replacement.

What’s the installed replacement cost in your area? In Houston, a straightforward garbage disposal installation Houston homeowners request most often falls in the 275 to 600 dollar range for a like-for-like 1/2 or 3/4 horsepower unit, parts and labor included. If a repair quote approaches half of that for a unit near the end of its lifespan, replacing is the better long-term play.

Anecdote from the field. I once serviced a Westchase townhome with a decade-old 1/3 horsepower unit that had a hairline crack at the bottom seam. The leak only appeared during long runs, so the homeowner thought it was the sink flange. We could have re-puttied the flange for 180 dollars, but it wouldn’t solve the leak. Replacement, including a bump to 1/2 horsepower and a switch from hardwire to cord-and-plug, came to 385 dollars. That job prevented a return visit and a warped cabinet floor that would have cost more than the disposal itself.

What Counts as “Affordable” in Houston

“Affordable garbage disposal repair” sounds simple, but the word hides a lot. On one end, you can find a handyman advertising 60-dollar house calls. On the other, a large franchise might quote 250 dollars just to arrive, then credit that toward service. True affordability balances cost with risk, warranty, and long-term function.

Houston’s sensible middle typically looks like this. A diagnostic fee of 49 to 89 dollars that gets applied to any approved repair. Transparent pricing for common tasks. A minimum labor block of 30 disposal humming but not spinning to 60 minutes. A written warranty, even if short, on both parts and labor. And clear boundaries on what happens if the tech discovers a larger issue.

Many small, reputable outfits keep overhead low by scheduling smart routes and stocking common parts: gaskets, clamps, splash guards, strain reliefs, and a few popular disposals. That efficiency is where you get real value, not in squeezing the hourly rate to the floor.

How to Compare Quotes Without Getting Lost in Details

When you call around for garbage disposal repair, ask the same questions to each company so you can compare apples to apples. Keep notes. Clarify exactly what is included so a “cheap” quote doesn’t balloon once the tech is under your sink.

Here is a compact checklist that helps cut through the noise:

- Do you charge a diagnostic fee, and is it applied to the repair?

- What are your typical prices for a jam clear, flange reseal, and unit replacement?

- Is there a warranty on labor and parts, and for how long?

- Do you stock disposals on the truck if mine needs replacement today?

- What is the earliest arrival window, and do you offer photos or names of the tech for security?

Notice none of those are trick questions. A good company has ready answers. If the person on the phone hesitates about warranty terms or gives only vague ranges, treat that as a sign to keep looking.

The DIY Line: What You Can Safely Try Before Calling

There are a few things you can do that pose little risk if you use common sense and keep your hands out of the chamber while the unit is powered.

Use the reset button. If the unit overheats, it trips the thermal overload. Turn off the switch, press the red reset button on the bottom, then run cold water and try again.

Free the flywheel. Many disposals have a hex socket at the bottom. Insert a 1/4 inch Allen wrench and gently rock it back and forth to release a jam. Always cut power at the wall switch first. If hardwired, flip the breaker.

Inspect the sink flange. If water appears around the top of the disposal, look for a cracked or brittle splash guard or a loose mounting ring. You can tighten the ring with a screwdriver in the tabs. Over-tightening can twist the flange and break the seal, so go easy.

Check the trap. food waste disposer service If you’re comfortable with basic plumbing, place a pan, loosen the slip nuts on the P-trap, and clear debris. Reassemble with the washers facing the right direction. Don’t use excessive force on old plastic fittings.

If you smell electrical burning, see a leak from the bottom seam, or the unit trips immediately after reset, stop. That’s where a trained tech earns their fee. Any attempt to disassemble the motor housing is a dead end for homeowners, and it voids warranties.

What Makes Kitchen Disposal Repair Houston-Specific

Houston homes present quirks that affect price and complexity. Many older bungalows in the Heights or Eastwood have galvanized or cast-iron waste lines that scale up and narrow over decades. Clearing these without damaging threads or compromising joints takes finesse. Midtown and Galleria high-rises add access rules and service elevator schedules that stretch appointment windows and add fees. Newer suburban homes in Katy or Pearland often have builder-grade 1/3 horsepower units that struggle with modern cooking habits. Upgrading to 3/4 horsepower can be a smart move because it reduces jams and noise, and it supports a small family that cooks most nights.

Then there’s humidity. Warm, damp air accelerates corrosion on mounting rings and screws. You’ll see rusted lugs under sinks that sat over damp cabinets during a slow leak. The fix can be as simple as new hardware, or as complicated as cutting seized bolts. A tech who has worked Houston for years will carry penetrating oil, spare rings, and patience.

Picking the Right Replacement, Without Buying More Than You Need

If you decide to replace, you’ll face a wall of models and horsepower ratings. Bigger isn’t always better. Here’s how to think about it in context.

Horsepower. 1/3 horsepower is entry-level, suitable for light use. It’s more prone to jams. 1/2 horsepower is the common baseline for small households. 3/4 horsepower offers stronger torque and tends to be quieter, with better sound insulation. One horsepower models are powerful but oversized for small kitchens and often need dedicated circuits.

Grind technology. Multi-stage grinding helps with fibrous foods but isn’t essential. A well-designed single-stage 3/4 horsepower unit handles most scraps a home should put down the drain.

Noise. Sound insulation matters if your kitchen is open to living space. The difference between a budget 1/3 horsepower and a mid-tier 3/4 horsepower can be night and day.

Mount type garbage disposal replacement cost and compatibility. Many brands use a three-bolt mounting assembly. If your sink already has one, sticking with the same style streamlines the swap. That can shave 30 to 60 minutes off labor.

Electrical. If your current unit is hardwired and you prefer a plug, a tech can install a cord kit and, if there’s no outlet, quote the cost to add one. In Houston, adding an outlet under a sink varies widely, from 120 to 350 dollars, depending on panel proximity and whether GFCI protection already exists on the circuit.

Warranty. Most disposals carry a 2 to 7-year warranty. Read the fine print. Some cover in-home labor for defects, others only parts. Reputable installers will register the product for you.

From a budget view, installed costs for a quality 1/2 horsepower unit in Houston often sit near the 325 to 450 dollar mark. A quieter, stainless-grind 3/4 horsepower model typically lands between 425 and 650 dollars, depending on brand and site conditions. If you’re quoted 800 or more for a straightforward swap without electrical changes, ask for a breakdown of parts and labor.

The Hidden Costs That Inflate “Cheap” Jobs

The easiest way to overspend is to chase the lowest advertised rate without asking what it excludes. Some pitfalls to avoid:

No credit for diagnosis. If a company charges a 99-dollar trip fee and refuses to apply it to the repair, your total climbs fast for simple fixes.

Generic “parts” line items. A vague 200-dollar parts charge for a gasket and two clamps is a red flag. Ask for an itemized parts list, or at least a clear description. Reasonable markups are normal, but they should be defensible.

Mandatory add-ons. Splash guards wear out, but replacing one should be optional unless it is actually torn or warped. Dish drain branch tailpiece replacements should be quoted only if the existing piece is leaking or corroded.

Unnecessary upsells. You do not need an oversized horsepower unit for a one-bedroom apartment, nor a hardwire-to-plug conversion if your existing wiring is safe and code-compliant.

If you feel boxed in, it’s fine to pay the diagnostic fee and get a second opinion. Most companies expect that and will compete for your business if you share the other quote.

How Scheduling, Season, and Access Affect Price

Houston storms change the job board. After a heavy rain, you’ll see more drain line calls and fewer discounted appointment slots. Holiday weeks bring a wave of kitchen disposal repair Houston families need after big meals. If you can plan the work midweek, midday, you can often land lower rates or faster windows. Some shops offer first-call-of-the-day slots at a small premium because they are easiest to keep. If your building requires a certificate of insurance or advance booking for the service elevator, mention it when you call. The dispatcher can set realistic windows and prevent rescheduling fees.

Access matters under the sink too. A disposal wedged behind a reverse osmosis tank with rigid lines will take longer. Clear the cabinet before the tech arrives. Bag up cleaning supplies and pull the trash can. That simple prep can shave 10 to 20 minutes off the visit, which some companies reflect in lower labor charges.

What a Professional Visit Looks Like

A solid service call has a predictable rhythm. The tech confirms the symptoms and turns on water and power to observe. They check the reset, test the switch, and listen for hums or rattles. Then they cut power at the switch or breaker, verify with a non-contact tester, and inspect the chamber, mount, and connections with a flashlight. If a jam is suspected, they use the Allen socket to free the flywheel, then check rotation by hand through the chamber with a tool, not fingers.

If a leak is reported, they dry the unit and run water to pinpoint the source. Top leaks implicate the flange or the dishwasher inlet. Side leaks point to the discharge elbow. Bottom leaks suggest housing failure. Good techs explain what they see before proposing a fix, and they’ll show you with the light so you can confirm.

Repairs are executed cleanly, with towels under the unit to protect your cabinet floor. When replacing, they catch the old unit as it drops, remove the old putty, reseat the flange, and make connections with new gaskets. They test for electrical safety, run water, check for leaks, and take away the old unit for proper disposal. The visit ends with a quick review of what changed, any warranty coverage, and basic use tips.

Getting True Value From “Affordable Garbage Disposal Repair”

When you hear Affordable Garbage disposal repair in an ad or see it in search results, look past the headline. Value comes from three elements working together.

The right scope. You pay for the fix you need, not extra parts or speculative work.

Efficient execution. A tech who arrives with the right tools and parts spends less time, which lowers labor. Stocked trucks matter here.

Accountability. A warranty on labor, even if 30 to 90 days, pushes the company to do it right the first time. For replacements, look for at least one year on labor paired with the manufacturer’s parts warranty.

A brief example. In Spring Branch, I quoted a flange reseal and splash guard replacement at 210 dollars after a 59-dollar diagnostic that rolled into the total. Another bid at 140 dollars seemed lower until it added a 99-dollar “shop supplies” fee and 60 dollars for disposal haul-away. The all-in totals flipped. Transparency wins.

Preventive Habits That Save You Calls

Disposals aren’t delicate, but they dislike specific behavior. Run cold water before, during, and after use to flush particles. Avoid large dumps of potato peels, eggshell membranes, or stringy greens. Those form mats that jam impellers. Cut citrus rinds into small pieces. Skip coffee grounds if your branch line is already sluggish. Grind with short bursts rather than long continuous runs when clearing plates.

If you have a dishwasher connected to the disposal, make sure the knockout plug was properly removed during installation. A surprising number of new installs leave that disk in place, which sends dishwasher water back into the tub or onto your floor. If you notice poor dishwasher draining right after getting a new disposal, that’s the first thing to check.

When You Need More Than a Disposal Fix

Sometimes disposal symptoms mask bigger plumbing troubles. Slow drains that return days after a clean trap can signal a partial blockage farther down the line. A sewer camera inspection, while not cheap, can save repeated service calls. In older parts of Houston with mature trees, roots find clay joints and invade. If your kitchen line ties into an older branch with bell-and-spigot joints, a disposal won’t push ground food past a root mass. In these cases, a plumber should address the main issue, and your disposal will behave again.

Similarly, a GFCI that trips when you run the disposal and dishwasher together may point to a circuit load issue or a wet outlet box under the sink. A licensed electrician can evaluate whether the dishwasher and disposal share a circuit improperly. Code and safety beat temporary workarounds.

Final Thoughts: A Clear Path to a Fair Repair

Affordable doesn’t mean cheapest. It means the right fix, at a fair price, with a result that lasts. For garbage disposal repair in Houston, that usually looks like a modest diagnostic fee, an upfront range for common tasks, a truck stocked with gaskets and a few solid disposals, and a tech who will show you the problem before charging to solve it. If your unit is younger than five years and the issue is a simple jam or flange, repair it. If your unit is older, loud, or leaking from the housing, replace it with a 1/2 or 3/4 horsepower model that suits your cooking habits.

If you do choose replacement, timing matters. Booking a midweek appointment outside of peak holiday windows can trim costs and reduce wait times. If your home sits in an older neighborhood with vintage plumbing, choose a company that understands those materials. If you’re in a high-rise, mention building requirements on the first call.

One last nudge for the budget-minded. Keep a 1/4 inch Allen wrench in a drawer, learn where your disposal reset button lives, and get in the habit of running cold water during use. Those three habits can prevent at least half the service calls I see. And when you do need help, you’ll be a better buyer, and you’ll pay for skill instead of confusion.

DYZ Plumbing, LLC

Address: 1220 Blalock Rd, Houston, TX 77055

Phone: (832) 877-9600