Houston Garbage Disposal Repair: What Causes Frequent Resets

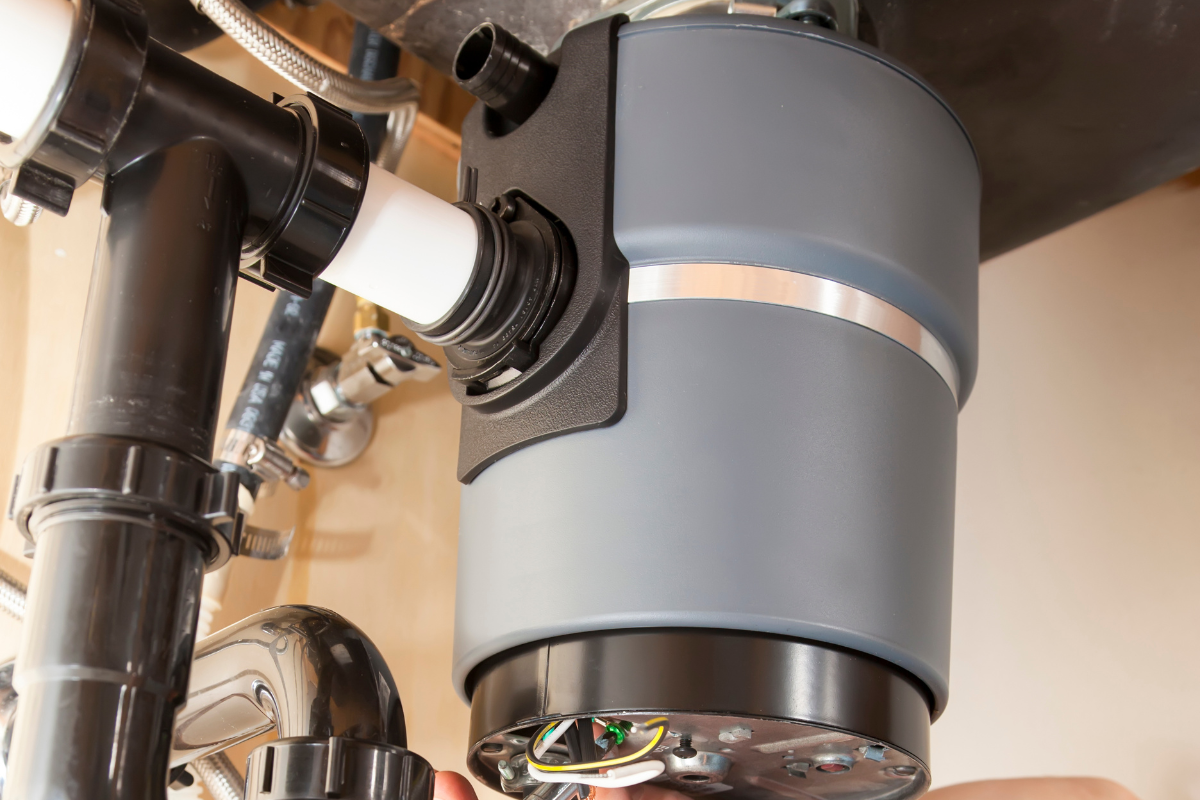

A garbage disposal that trips every few uses is more than a nuisance. It hints at an electrical safety device doing its job while something else is off kilter: motor load, wiring, water intrusion, or simple misuse. In a Houston kitchen, where heat, humidity, /2 HP disposal upgrade and heavy cooking collide, disposals work hard. Understanding why the red reset button keeps popping can save you a service call, or at least help you speak the same language as a technician when repair is unavoidable.

I work on disposals year-round across Harris County. Most frequent resets trace back to a small set of root causes. The patterns repeat: a new homeowner inherits an undersized unit, a remodel introduced a misaligned flange, or a well-meaning cook fed the chamber with fibrous scraps. Once you learn the cues, you can usually pinpoint the culprit with a flashlight, a hex key, and a few minutes of observation.

What the reset button actually does

The reset button is a built-in thermal overload protector. When the motor overheats or draws too much current, the device opens the circuit and the disposal shuts off. After things cool down, that red button re-latches the switch and power returns. Safety first. What trips it? Excess heat from a locked rotor, high friction from failing bearings, or prolonged heavy load from tough waste. Sometimes the trigger is a wiring or voltage issue rather than the motor itself.

Not all trips mean failure. One-off resets happen after a jam or a brief stall. Persistent resets signal a chronic condition that will not fix itself.

How Houston kitchens stress disposals

Climate and use patterns matter. Houston’s humidity encourages corrosion on motor housings and terminals. Limescale and mineral deposits from our water can roughen the grind ring, increasing friction. Summer storms and brownouts create voltage swings. And many households here cook big and often: crawfish boils, backyard barbeques, and tamale prep produce bones, shells, stringy husks, and lots of starch. Those items challenge even premium disposals. The combination amplifies the risk of frequent resets.

The big five reasons disposals keep tripping

I see a long list of edge cases, but five categories cover most repeat resets.

Motor overload from hard or stringy waste. A disposal is not a wood chipper. Long fibers from celery, corn husks, onion skins, and artichoke leaves wrap around the flywheel, stalling the impellers. Bones and fruit pits create localized jams. Dense starchy foods like rice, pasta, and potato peels turn into paste that packs beneath the turntable. The motor draws extra amps in all these scenarios. After a minute or two of strain, the overload opens and you find yourself reaching for the red button.

Dull grind components and tired bearings. Disposals do not have blades in the knife sense, yet their grind ring and impellers do wear. A seven-year-old builder-grade unit that handled daily use may have rounded nubs and grooved rings. That wear means more time per load and more heat. Bearings go next, adding friction and a high-pitched whine before the reset trips. If you hear a grind that used to be crisp now sounding muddy, or if you smell hot electrical insulation after short runs, age-related wear is probably at play.

Electrical issues, from wiring to voltage. Loose wire nuts inside the junction box beneath the sink can arc and create heat, which sometimes transfers into the disposal housing. A shared circuit with a high-draw appliance can dim voltage under load. Houston’s grid, especially during storms, can sag and surge. Motors do not like low voltage; they pull higher current trying to maintain torque, and the overload reacts. In older homes, a disposal tied to a worn wall switch or a tired GFCI may see intermittent power that runs the motor hot.

Water intrusion and failed seals. The sink flange and splash guard are your first defense. If the plumber’s putty dried and cracked, water drips into the housing, rust follows, and electrical insulation breaks down. A slow leak from the dishwasher drain connection can wick moisture into the motor cavity. Inside the disposal, a failing lower seal allows water to reach bearings and windings. You will notice rust trails, a constant drip from the bottom, or a faint buzzing and instant trip when you try to run it.

Improper installation or unit mismatch. A half-horsepower unit serving a family /7 plumbing service Houston of six that frequently grinds fibrous vegetables sits at a disadvantage. Builders often install compact, inexpensive models to save space and cost. The disposal still functions, but it lives at the edge of its power curve, which means frequent overloads. Bad alignment at install also matters: if the mounting ring is slightly cocked, the flywheel can rub. Add a kinked discharge line or a mis-sized p-trap that slows drainage, and the chamber stays full of slurry, straining the motor.

How to tell which problem you have

Before you assume the worst, read the signs your disposal gives you. Each failure mode has a distinct feel.

If you hear a hum followed by an instant click, the motor is locked or the capacitor is failing. The hum means power is reaching the motor, but the rotor cannot spin. A jam by a foreign object like a coin, bottle cap, or small bone piece is likely. The reset button will pop quickly because the current spikes.

If it runs for 15 to 45 seconds then trips, you are looking at overload from tough material, dull grinding parts, or a worn bearing that heats up under sustained load. The longer delay points to heat accumulation rather than an electrical fault.

If you press reset and nothing happens until several minutes later, thermal overload needs time to cool. That points to heat, not a wiring interruption. Persistent long cool-downs suggest inadequate ventilation around the motor or aggressive loads.

If it trips when other appliances kick on, suspect electrical. A disposal tied to the same circuit as a microwave, toaster oven, or space heater may be starved for voltage under combined demand. The timing of the trip will track with those devices.

If you see dripping from the bottom of the housing, set a towel and do not run it again until the leak source is found. Water and electricity do not compromise well. Frequent trip plus a leak almost always means internal corrosion and a short service life unless corrected quickly.

A careful at-home diagnostic

DIY checks can be safe if you respect power and water, and they often save time. The limits are clear: if you see damaged wiring, feel heat at the switch or junction box, or if the unit trips the breaker as well as the reset, call for professional help. For routine stalls, a simple sequence solves many cases.

-

Turn off power at the wall switch, then unplug the disposal under the sink or shut off the breaker. Shine a flashlight down the drain. If you see a foreign object, use tongs or needle-nose pliers to remove it. Never reach in with fingers.

-

Insert a 1/4-inch hex wrench in the bottom center hub of the disposal and gently rock it clockwise, then counterclockwise to free the flywheel. If it moves smoothly, the jam is likely cleared. If it binds or grinds, continue gentle motion, do not force it.

-

Restore power, press the red reset button on the bottom until it clicks, run cold water full blast, and flip the switch for a short 2 to 3 second burst. If it spins and drains cleanly, run another 10 seconds to flush. If it hums again, cut power immediately and revisit the hex wrench step.

This quick process resolves many jam-related trips. If the disposal returns to normal for a few days and then the cycle repeats, check your habits. Fibrous scraps are probably sneaking back in.

Habits that prevent frequent resets

Half the calls I make could be avoided with small changes in how the disposal is used. The point is not to baby the unit, but to feed it in a way that keeps the motor cool and the chamber clear.

-

Run a strong stream of cold water before, during, and 10 to 15 seconds after grinding. Cold water keeps grease firm so it can be chopped and moved. The post-run flush carries particles through the trap.

-

Break up grinding sessions. Feed food waste gradually. A handful, a pause, another handful. Continuous heavy loads overheat the motor more than short bursts.

-

Keep fibrous materials and heavy starch out. Corn husks, celery strings, leek greens, artichoke leaves, and banana peels wrap. Rice, pasta, and mashed potatoes swell into paste. Compost these instead.

-

Avoid whole bones, pits, and shells. Chicken wing tips or fish bones occasionally pass, but you pay in wear. Fruit pits and shell fragments dull the grind ring.

-

Refresh with ice and citrus rinds occasionally. A handful of ice with a few lemon or lime rinds scours the chamber surface. Do not expect it to sharpen metal, but it keeps gunk from building.

These simple practices reduce heat and friction, the two culprits behind most trips.

Installation details that make or break performance

When I pull a disposal that constantly trips, the install often reveals itself as the root of the problem. The devil hides in small tolerances.

A properly seated sink flange and fresh putty matter. If the flange is crooked by even a couple of degrees, the flywheel can shave the housing lip under load. That creates a faint scraping sound that becomes pronounced with heat. Re-setting the flange fixes a surprising number of mysterious trips.

The discharge pipe needs free flow. If the outlet leads into a high trap or the pipe rises before dropping, you create a hydraulic choke. That keeps slurry in the chamber and makes the motor push harder. On many Kitchen disposal repair Houston visits, I rework the trap geometry, shorten an overlong tailpiece, or clear a dishwasher knockout plug partially cracked rather than cleanly removed.

Electrical connections must be tight and correctly rated. A disposal should be on a dedicated or lightly shared circuit, with wire gauge and breaker size suited to the motor. In older homes, the circuit sometimes shares with lights and outlets that sag voltage when the disposal starts. If your lights flicker when you grind, ask an electrician to evaluate the load. For new homes or remodels, choosing garbage disposal installation Houston services that coordinate plumbing and electrical avoids this mismatch.

Undersized units in busy kitchens struggle. A 1/2 HP builder model may be fine for a single-occupant condo. For a family cooking nightly, a 3/4 HP or 1 HP unit with stainless steel components handles stringy food and small bones without heating up. The cost difference is modest compared to the lifespan and convenience gains, especially when you factor Affordable Garbage disposal repair rates for repeated service calls.

When the problem is inside the motor

Not every issue is visible or fixable from above. Capacitors, bearings, and windings fail with age and heat. The symptoms vary, but you will notice patterns after years in the field.

A failing start capacitor leaves the motor humming without spin, then tripping. Tapping the housing sometimes jolts it into motion, which is a clear sign the capacitor is marginal. Replacing a capacitor is straightforward on some models and sealed on others. If parts are available and the housing is dry and solid, a repair makes sense.

Bearings announce themselves with a whine that rises with speed. Add heat and a burnt smell under the sink and you are close to the end. You can sometimes buy a few months by avoiding heavy loads and running shorter cycles, but frequent resets will keep coming as friction builds.

Shorted windings lead to immediate trips or breaker pops. If the breaker on the panel is tripping along with the disposal reset, do not attempt further DIY. At that point, plan for replacement.

Repair or replace: the practical calculus

In the field, I weigh cost, age, parts availability, and the customer’s kitchen habits. A five-year-old midrange unit with a jam or a loose wire deserves repair. A ten-year-old compact unit with a leak and frequent resets usually goes to recycling.

Consider these factors:

-

Age and build quality. Builder-grade disposals often last 5 to 7 years with daily use. Premium stainless units make 10 to 12 if treated kindly. If your motor is past its expected life and tripping frequently, replacement is usually cheaper than chasing multiple issues.

-

Extent of corrosion. A dry, clean housing invites repair, whereas a rusted base and water marks mean deteriorated seals. Replacing seals can be as labor intensive as a new install, with less payoff.

-

Compatibility with your kitchen. If you upgraded countertops and have a deep sink or tight cabinet, a compact high-torque unit may be a better fit. This is where experienced Garbage disposal repair technicians can measure clearances and recommend a model that clears your trap and dishwasher hose.

-

Warranty coverage. Many manufacturers cover parts for multiple years. If your unit is within warranty, repair through an authorized service center makes sense. Keep the purchase record handy.

For homeowners who want predictability, an upfront replacement to a stronger model paired with proper installation often costs less over five years than recurring service calls. When customers search for Garbage disposal installation Houston, the best value comes from installers who also do service, because they design with repair in mind.

What a professional technician checks that DIY often misses

A trained eye runs a quick but thorough diagnostic. I test amperage draw under no-load and load, check voltage at the junction box while the unit starts, inspect the sink flange for weep marks, and verify trap geometry and venting. I also feel for vibration that hints at misalignment. Many frequent-reset cases reveal a confluence of minor faults rather than a single smoking gun.

We also check the dishwasher air gap and hose height. If the dishwasher backflows into the disposal, food residue and soap accumulate around the splash guard. That buildup increases startup resistance and begins the cycle of heat and resets. Adjusting the hose loop and cleaning the guard can smooth operation immediately.

If there is a persistent odor, we look for hidden buildup. It is common to find a mat of fibrous pulp wedged between the shredder ring and housing. Removing it is simple with the right tools but awkward without. After cleaning, many units run cooler and stop tripping.

Cost expectations in the Houston market

Prices vary by neighborhood and urgency. A simple jam clearance or reset education visit might run a modest service fee. Rewiring a loose connection, replacing a switch, or swapping a strain relief can be done quickly and falls on the low end of the spectrum. Capacitor replacement lands in the middle, provided your model allows part access.

Bearing or seal issues push labor higher and generally point toward replacement. New disposal installation, including removal of the old unit, new flange, and alignment, typically ranges based on kitchen plumbing services horsepower and brand. When shopping for Affordable Garbage disposal repair, ask whether the provider includes a trap reconfiguration if needed, and whether they will test under load with the dishwasher running. Good outfits do both and stand behind the work.

If you lean toward replacement, plan for a model that matches your cooking style. A 3/4 HP with sound insulation and stainless internals is the sweet spot for many families. If you host crawfish parties or grind daily, a 1 HP unit buys headroom and runs cooler, so resets become rare.

Edge cases worth noting

Sometimes the oddball calls teach the most.

Occasional surge trips in storm season. After a lightning-heavy night, I see disposals tripping on first use. A surge could have wounded the capacitor. If the issue disappears after a reset and does not return, chalk it up to a one-time electrical event. If it recurs, test the start circuit.

Builders leaving the dishwasher knockout partially attached. A new homeowner complains of weak grinding and frequent trips. The discharge looks open, but a small crescent of plastic remains. Water backs up, the chamber stays full, and the motor labors. A careful punch-out and file smooth fixes it in minutes.

Paint cans and solvent rags under the sink. Off-gassing solvents heat the space and degrade rubber components. I have opened cabinets that felt like small ovens in August, with poor ventilation and warm air rising. The disposal runs hot from the start and trips early. Clearing the cabinet and improving airflow helps more than you would think.

Water softeners feeding the kitchen sink. Softened water can change the way fats congeal and move through the grind chamber. Users sometimes run less water, thinking the soft water helps. The opposite happens, and pasty residues collect. Running a stronger flush and occasional ice scrubs counteracts it.

Keeping a disposal healthy in Houston’s climate

The combination of humidity and heavy cooking means Houston kitchens should adopt a few routines to avoid frequent resets and extend disposal life.

Wipe and dry the cabinet floor if you see any dampness. Catching a flange drip early stops corrosion from creeping into the motor housing. If you smell mustiness, track it down before it becomes a leak that shorts the unit.

Every month, run a maintenance grind. Ice and a citrus rind, followed by a long cold-water flush, keeps debris from nesting in corners. If you rarely use the disposal, still run it weekly. Idling units seize bearings faster than busy ones.

Replace splash guards when they get loose or torn. A floppy guard lets debris rebound into the chamber, lengthening grind time. It also invites back-splash that wets the housing.

If you remodel or swap sinks, involve someone who understands trap geometry and dishwasher tie-ins. The sleek farmhouse sink might drop the drain too low for your old trap layout, creating a hydraulic headache. Thoughtful Kitchen disposal repair Houston services consider these details so the new look also works under the hood.

When to call for help

Call a pro if the breaker in the panel trips along with the disposal reset, if you see or suspect a leak inside the motor housing, if you smell electrical burning, or if the unit hums and trips despite clearing the chamber and using the hex wrench. If the disposal is under warranty, opening sealed components may void coverage, so a service call protects your claim.

When you reach out, describe the symptoms clearly: how long it runs before tripping, noises you hear, smells, and whether other appliances affect it. Mention recent storm activity or remodels. Good technicians diagnose faster when they have context. If you need both diagnosis and potential replacement, ask whether the provider handles both Garbage disposal repair and installation so you do not need two visits.

The bottom line

Frequent resets point to heat or electrical strain, not bad luck. In Houston, the combination of climate, power events, and heavy kitchen use makes disposals work harder. Most issues fall into clear categories: jam-prone waste habits, aging and dull components, electrical mismatches, water intrusion, or installation quirks. You can solve many of these with mindful use and simple checks. For the rest, local expertise matters. Skilled technicians who handle Affordable Garbage disposal repair and full replacements see the patterns every day and can tailor a fix to your kitchen, your cooking style, and the way your plumbing is actually built, not how it looks in a brochure.

Once corrected, a well-sized, well-installed, and well-used disposal should run for years without asking for that red button. That is the goal: a quiet grind, a clean drain, and no surprises when you flip the switch.

DYZ Plumbing, LLC

Address: 1220 Blalock Rd, Houston, TX 77055

Phone: (832) 877-9600