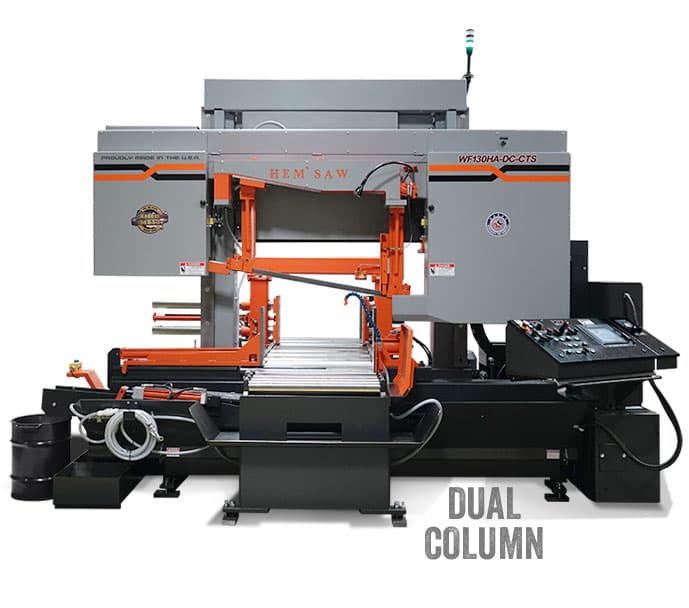

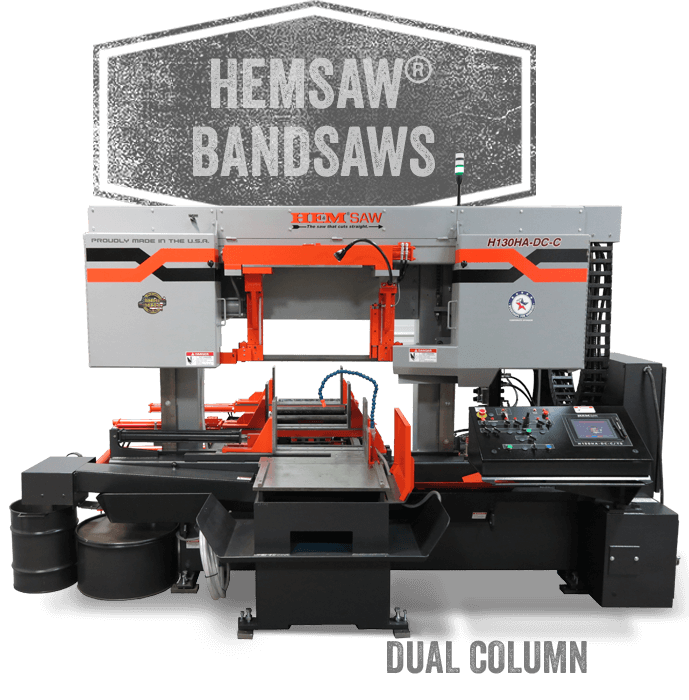

Band Saw Description

Band Saw Machine For Wood Cutting

Generally, horizontal saws are mounted on the ground. They are useful in making basic cuts using different materials.

Voortman is a leading manufacturer of high-quality industrial-grade bandsaws that can be used in workshops.