Materials

Each air circuit connects to its set suction cups (blue/red pipes). * Double visual and audible alert system in the event of an air drop.

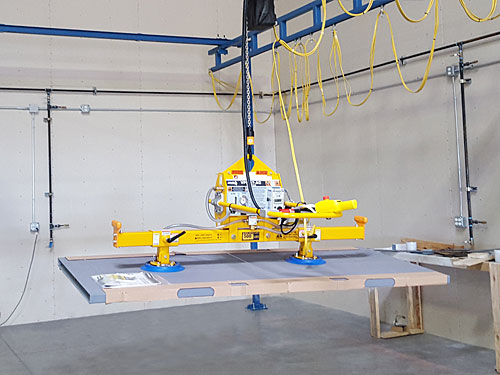

The ergonomic vacuum lifting equipment can transform your material handling. The Gulf States Saw & Machinery Co. Inc Multifunctional Lifter is the best vacuum lifting device in this industry. It can lift, lower and move most goods up to 600 lbs in any environment and under all conditions.