Solutions

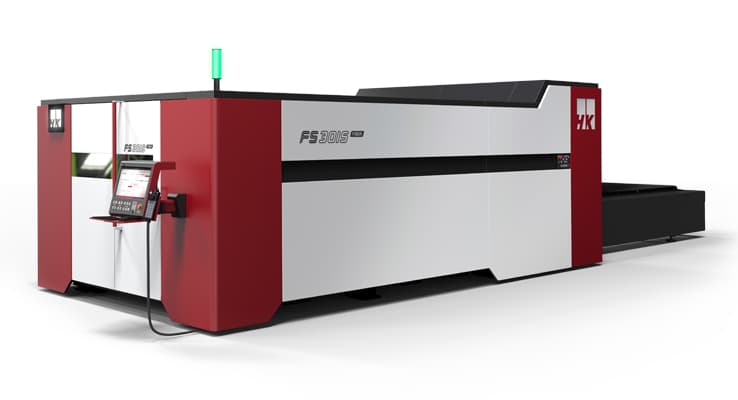

From subassemblies to fully functioning and tested equipment, we manufacture complete industrial systems.

At GSS Machinery, we pride ourselves on our unique processing capabilities, utilizing the latest technologies in software, tooling and machining, which allows us to deliver on our promises.