Although we offer many advantages we also stand out in two key ways. Firstly, we do not accept sub-par quality. We demand the highest quality from ourselves and our supply chains. Although many shops advertise excellent quality, very few actually deliver. Our process controls, rigorous inspections and expert quality staff are what makes the difference. Our commitments and customers are second. GSS Machinery's core value is integrity. Building partnerships is built on integrity, hardwork and reliability.

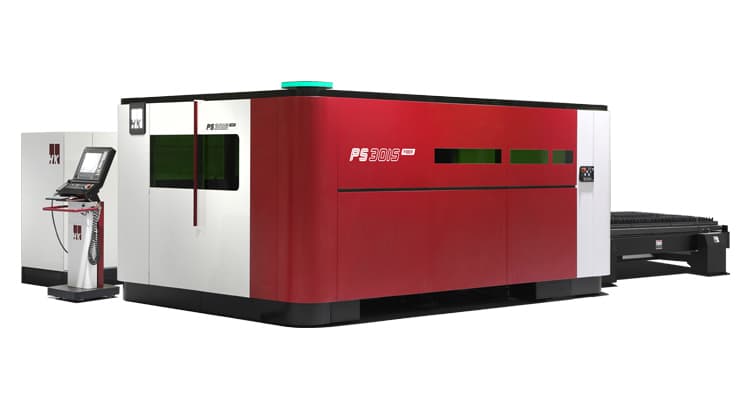

Our facilities include specialized machine tool, robotic welding, controlled environment areas, and support by highly skilled staff in custom and precision fabrication.