Machinery

Our VACAM control software is installed on every machine. Each machine shares the same "look-and feel", which reduces the learning curve. VACAM's open platform lets you exchange production data with MRP and ERP softwares, giving you real-time insight into your projects' progress. VACAM displays your workflows in real time and instantly analyzes imported product data. The software automatically proposes the most efficient solution to any problems. This ensures that your production does not get interrupted and increases the efficiency and runtime.

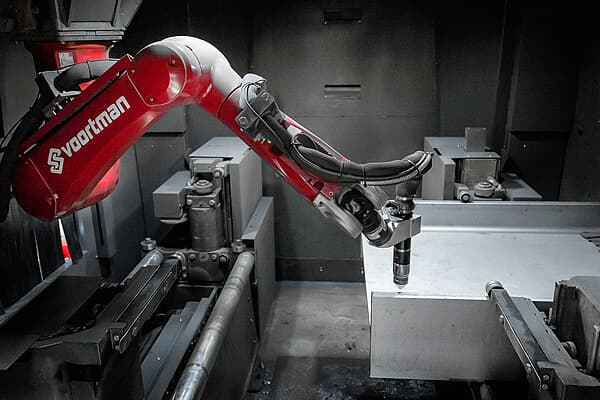

The V808 can do it all. Fabricators have hard-to-beat costs savings when using robotic plasma processing to do their drilling, millings, sawings, punchings, shearing, marking and other tasks. Combining these processes into one machine reduces the need for multiple machines with different functions.