Robot Coping Machine Vision Uses

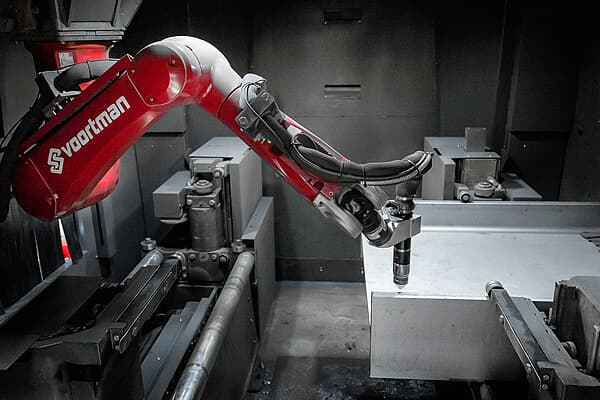

The V808 has an 8-axis, agile cutting robot that can reach and process all widths of profiles. Voortman added two additional axes to the six of the Panasonic robot's axes, giving the machine a wide reach that can be placed underneath the raw material. Voortman programmed the robot so that it moves in the most stable place, which improves the quality of the cutting.

Gulf States Saw & Machine Co. is the market leader 3D pipe profilers for over 35+ years. They were the first to offer a robot beam profiling machine capable of cutting all saddles, chamfers or slots: the RPC 1200 Mk3. We have fulfilled a long-standing customer demand by creating a beam-coping machine that profiles beams, channel, square tubes and angle bars as well as pipes, plates, t-bars and bulbs.