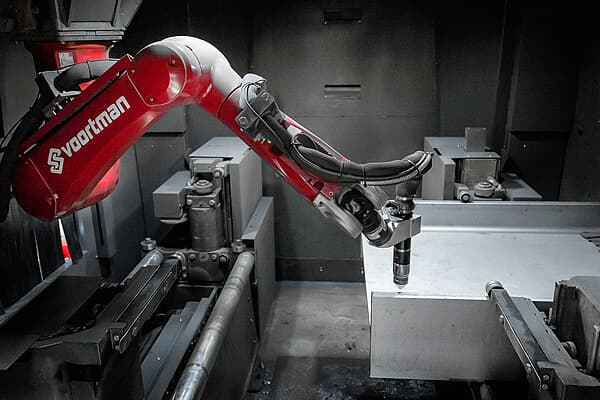

Robotic Coping Machine Folding

We created a real-time processing demo product to show you that the Voortman V808 is the fastest robotic thermal cutting machine in the market. Watch the video below to see the speed of the Voortman V808 yourself. The product below contains 12 different actions, all done by one machine:

Manual coping involves taking every step by hand. This includes reading the drawings and measuring the dimensions. Manual coping is labor-intensive. It requires extensive grinding and chipping to achieve desired results. You run the risk of making mistakes regarding angles, dimensions, finishes, misalignment, or inconsistencies. These inefficiencies lead to higher operational costs, and decreased profits.