Line Solution

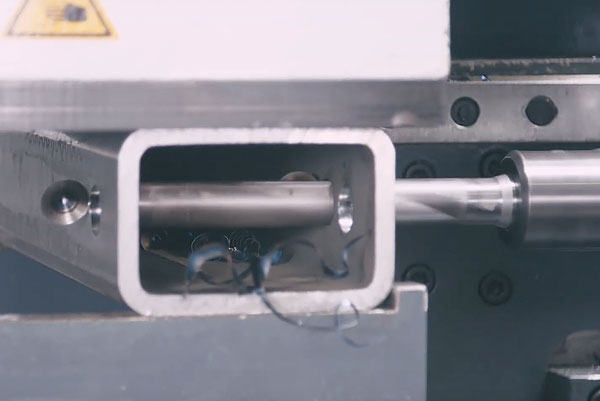

Voortman exclusively designed and built the CNC Beam Drill Line to fit GSS Machinery. Voortman oversees all aspects of the CNC Beam Drill Line, including warranty and service. Voortman acts as the service provider. GSS Machinery will always assist should the need arise.

Voortman offers ongoing training courses on all Voortman Ocean equipment at its Bradley Illinois facility. These courses are both for novice and experienced operators. These courses are designed to help employees leave your shop feeling more motivated, skilled and prepared to take on new tasks. For more information and pricing, please contact us.