Steel Fabrication

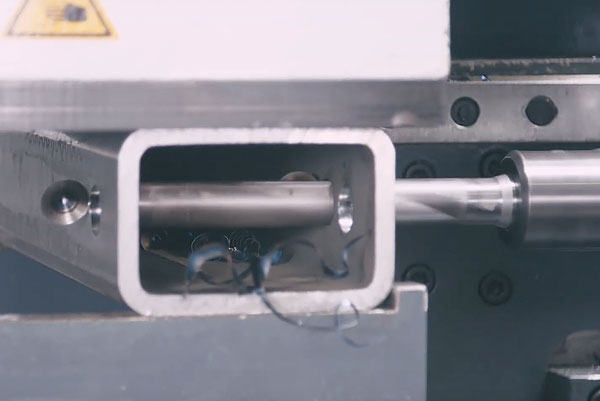

The Franklin HD145 (3) spindle-cNC drill is 44 inches wide. The HD-145 can lift beams of up to 750 lbs per feet. The high-performance spindle design allows drilling speeds of up to 2000 RPM. The rigid design of the spindle allows for very aggressive feed rates, up to 300 ft per minute. There are many material handling options available for the Franklin HD145, from 300 lbs to 750 pounds per foot.

The CNC Beam Drill Line is a hit among small and medium fabricators, who can fabricate both structural steel as well as miscellaneous metals. The CNC Beam Drill Line was first introduced in 2003 and has been used by more than 600 steel fabricators around the globe.