G Code Drilling

GSS Machinery receives a lot of questions from customers asking us which drill bits we should use. Are they insert bits or twist bits? We are committed to ensuring that our customers have the lowest cost per hole, which will make them more profitable and competitive. But, it is essential that they fully comprehend their options. Insert Drill Bit/Spade Drill Bit Advantages

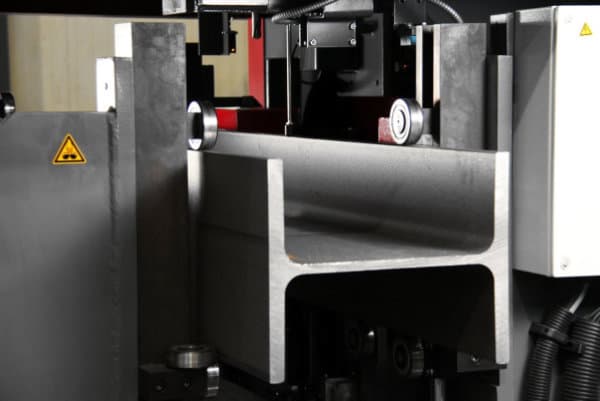

The CNC Beam Drill Line proved to be a big hit for small-to-medium fabricators that produce structural steel and miscellaneous material. Since its introduction in 2003, over 600 CNC Beam Drill Lines around the world have been installed. This machine has revolutionized the lives and livelihoods of many a steel fabricator.