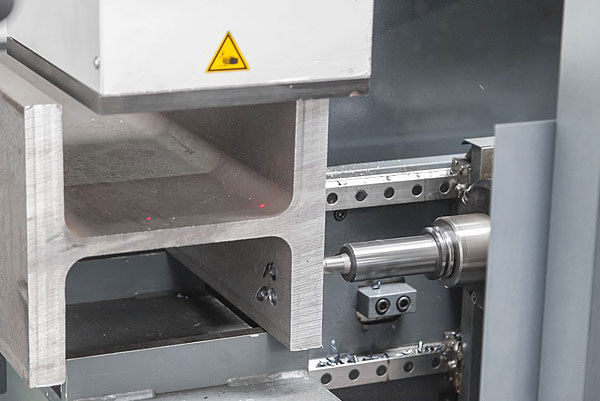

Voortman machinery is the worldwide leader in structural steel fabrication technology. Voortman machines provide steel fabricators with an advantage in the steel sector and allow them to maximize tonnage. Advantage-2 CNC beam drill is the core of any structural-steel fabrication shop. This machine is the heart of it all. It can drill endless carbide holes at high speeds, with multiple spindles, and at high speed. Advantage-2 is the most productive drill line in the steel sector. This drill line supports shops over the long term thanks to its heavy steel frame. The Advantage-2 is able to run profiles from one end to the other without any stops in production thanks to its roller feed design for the outfeed and infeed. Many fabricators around the globe use their Advantage-2s every year to make hundreds of thousands of tons steel.

Importing files directly to your steel detailing tool is preferable. It removes the need for an extra step and helps eliminate any possible errors. There are two distinct and separate camps in this regard.