Can We Drill On Beam

CNC Beam Drill Lines are space-efficient beam processing solutions. They require a minimum of 70ft by 9ft floor space. This makes it perfect for smaller fabricators and fabricators who have limited space. Many CNC Beam Drill Line installations are located outside, which allows for more fabricator space.

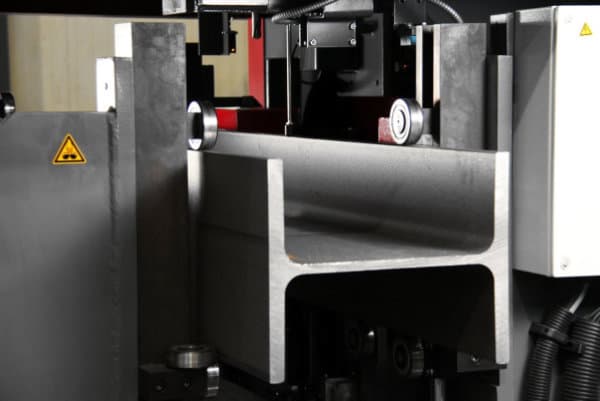

The Franklin HD145(3) spindle CNC drill is available in 44-inch width. The HD-145 can carry beams upto 750 lbs/foot. Hi-performance spindles provide drilling capabilities of up to 2,000 rpm. This rigid design delivers extremely high feed rates of up 300 surface feet per hour. You can have the Franklin HD145 equipped with various material handling packages, from 300 lbs per ft to 750lbs per ft.