Avenger

The CNC Drill Line can import DXF files and can use them to process 3-D shapes as long as the steel is detailed according to specific rules. Some of these rules might be different to the way you are detailing at the moment and might require some adjustment. This process is not nearly as seamless as the 3-D modeling software solutions above.

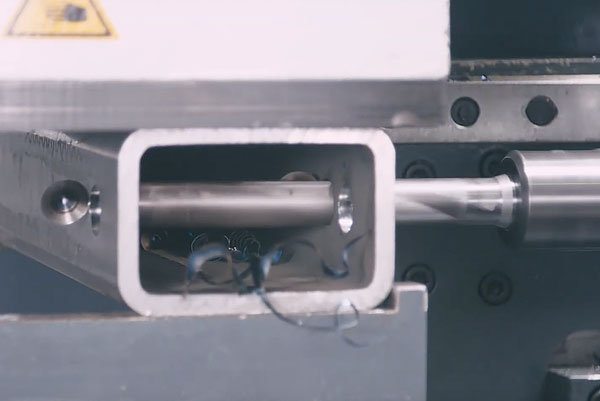

Z-Reader Probe-- The Z-Reader Probe can be used to locate the surface. It can be used to programmatically or manually. This option is not activated while cutting and is easily retracted. It can be used to verify the surface of each pierce, or to map the entire surface before cutting begins. It starts by initializing or zeroing the device to a surface at the start of a program. After that, it accumulates or tracks any difference.