Adm

"I believe without the help of the staff at GSS Machinery, we wouldn't be able to compete in the steel fabrication markets in which we are now competitive.

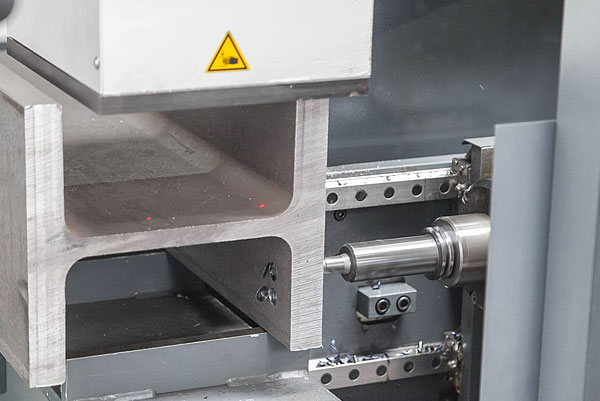

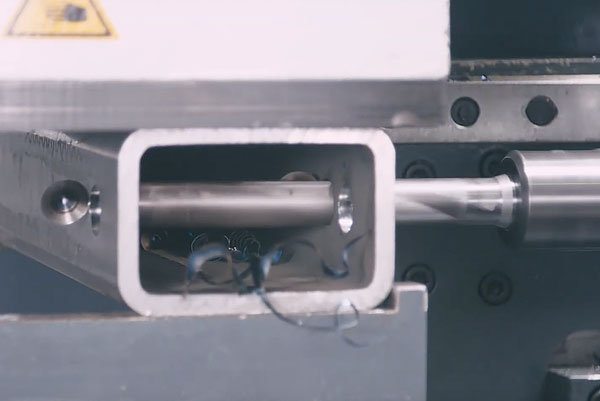

Continuous production? Check. You can check. The ability to process a profile in record time with triple-axis drilling and milling is possible thanks to the use of three axes. High-speed Siemens spindle motors of 25 horsepower provide industry-leading hole penetration speeds. Additionally, each drilling axis employs ball screw feed positioning. The drill line boasts an advanced clamping system specifically designed to reduce vibrations. Extreme accuracy? Check.