Cnc Drill Line Of Credit

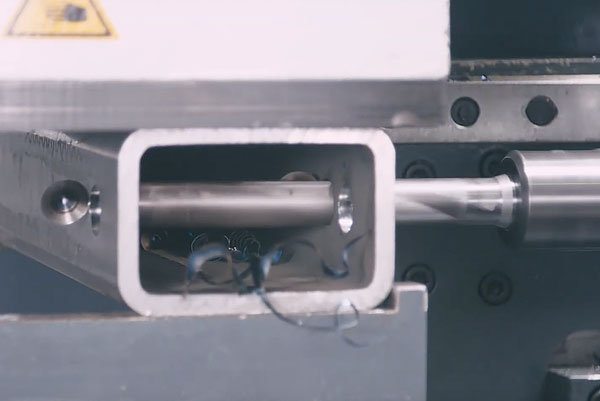

The Advantage-2 is powered via 25 HP (18.5kW), Siemens spindlemotors. It features 3 drill spindles that are equipped with 5-station tool changing stations. This powerful drilling technology ensures optimal operating time as well as drill hole quality.

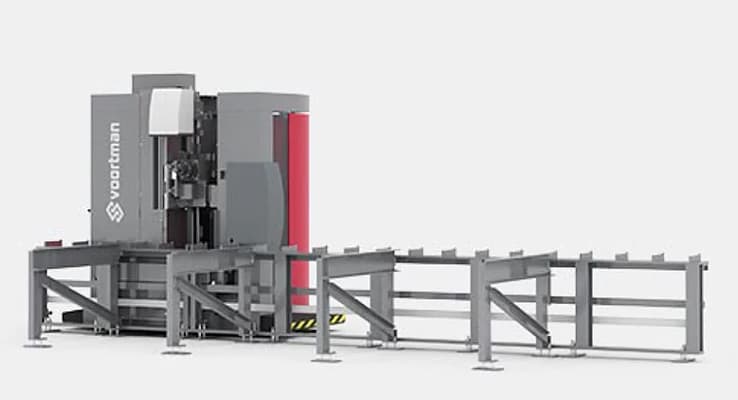

With its strong material handling support and precise measurement capabilities, the Advantage-2 CNC beam drill is perfect for tandem installations with any Voortman automated sawing system.