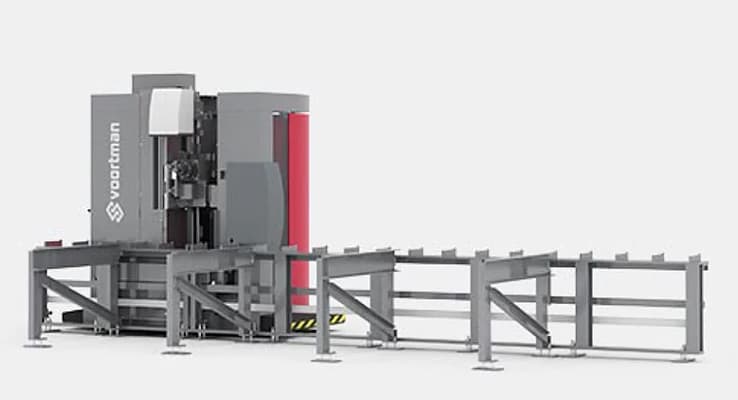

Multifunction

Voortman's CNC Beam Drill Lines may be part of a Drill Saw Line combined or larger, fully automated integrated production lines. Also known as Multi System Integration. It's easy to learn more.

The CNC Drill Line is easy to use and Avenger workers were the ones who laid the floors. There is no need to know anything about computers, and all training is given during the installation.