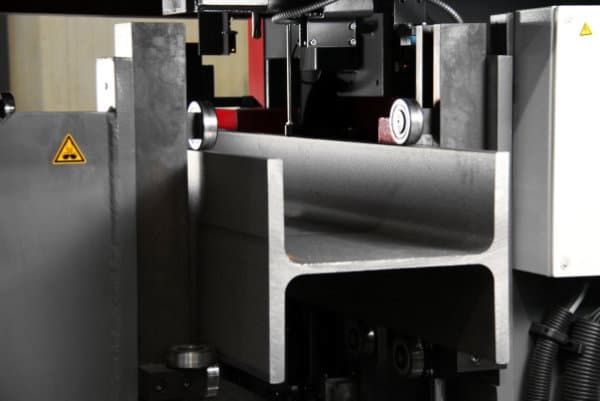

Structural Steel Beam Line

GSS Machinery offers a variety of drilling options to drill with your CNC Drill Line.

Over the past decade the UNIST MQL lubricant system has become the dominant coolant system in the USA, and has become standard equipment on the Aveger FORTY, Avenger PLUS and Clipper. This minimum quantity lubricant is an oil based coolant that promotes longer tool life. It is non toxic.