Cnc Drill Line 30

FlexBeam, a machine tool that produces steel profiles quickly and accurately, has just been launched. This machine can be used to process large jobs in small and medium-sized fab shops.

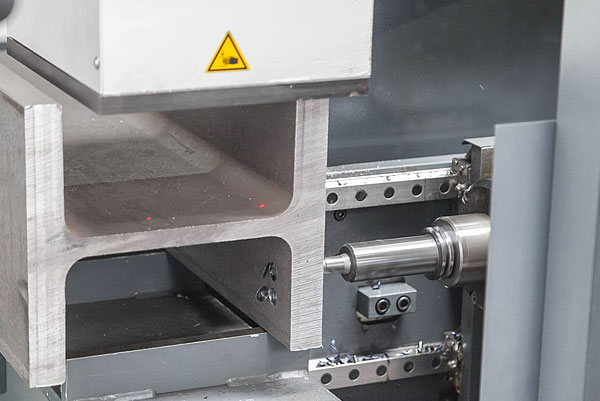

Voortman machines have been the global leaders in structural steel fabrication technology. Voortman machines are a key part of steel fabricators' competitive advantage. They can optimize tonnage and maintain a high level of quality. Advantage-2 CNC beam drilling is the heart of any structural steel fabrication shop. This machine is a core component of a high-speed multi-spindle, relentless caride drilling. Advantage-2 is one of the most profitable lines in the steel industry. This drill line is built from heavy steel and will last for many years. Thanks to the roller feed design of the infeed/outfeed, the Advantage-2 can run profiles from end to end without any stop in production. Every year, hundreds of fabricators around the world run hundreds of thousands and tons of steel through their Advantage-2s.