Cnc Drill Line Tab

Voortman's CNC Beam Drill Lines can be included in a Drill Saw Line, or in larger fully-automated integrated production lines. This is also known as Multi System Integration. Learn more!

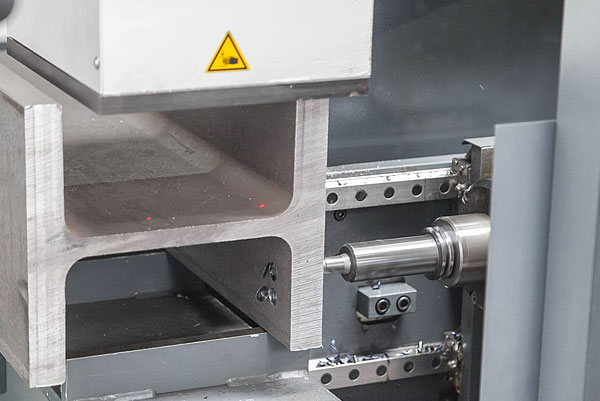

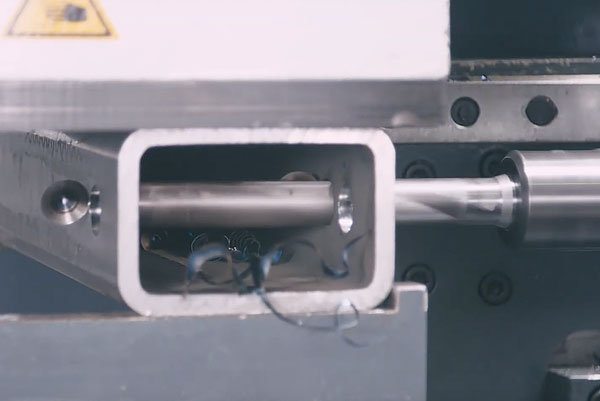

The Franklin HD145 (3) CNC spindle drill has a 44-inch width. The HD-145 can handle beams up to 775 lbs per foot. High-performance spindles are capable of drilling at speeds up to 2,000 RPM. This rigid design allows for extremely fast feed rates of up to 300 feet per minute. You can order the Franklin HD145 with a variety of material handling packages, ranging from 300 lbs per feet to 750 lbs each foot.